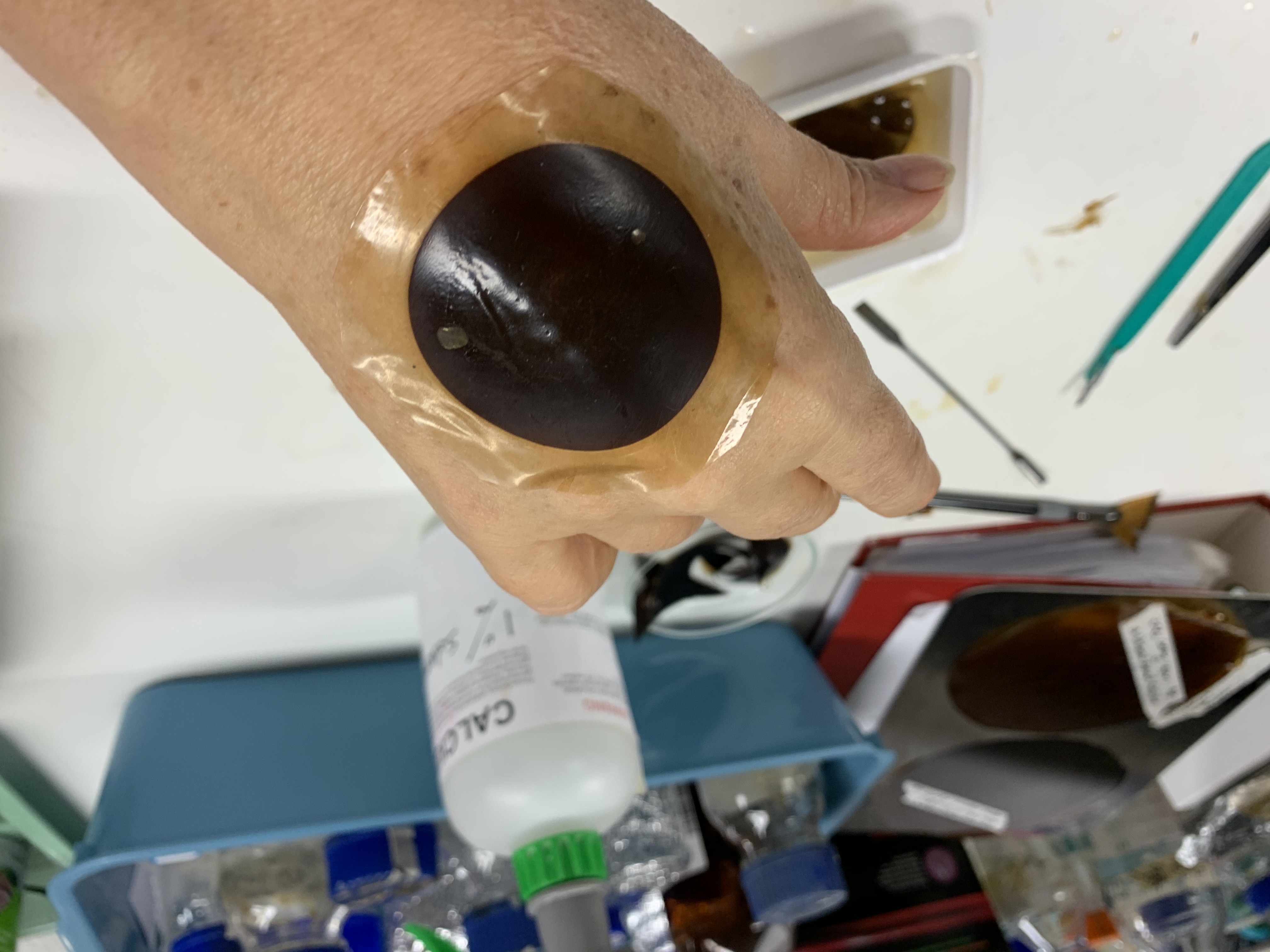

The concept below was met with a variety of responses from laboratory staff. They were invited to perform a sensory test by rubbing the polymer between their palms. I viewed this as something akin to Relational Aesthetics, where concern is not with an art object but between the idea and social context. Reactions varied from laughter, embarrassment, curiosity, acceptance.

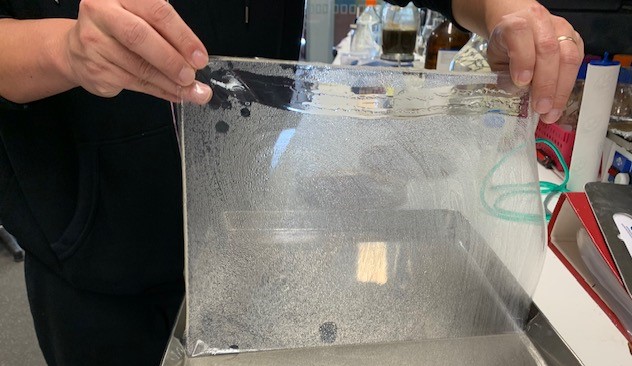

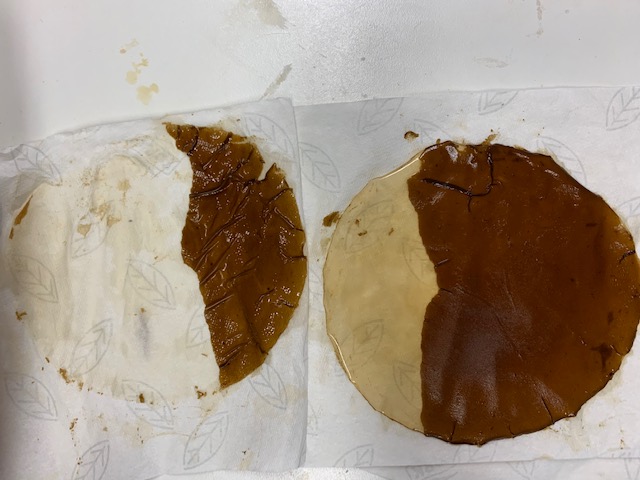

At CMBD we have been working with five main ingredients to create a range of seaweed-biopolymer materials.

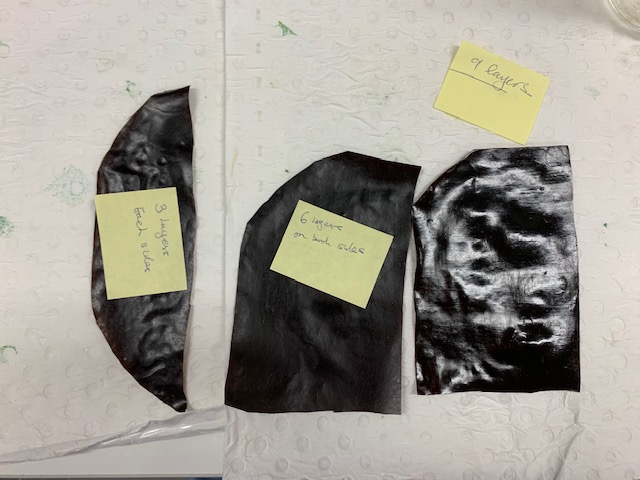

After experimenting freely with the physical properties of these ingredients, a systematic approach is now being undertaken to minimise the variables.

Marine Seaweed biopolymer ingredient physical attributes:

water- proof

water-soluble

heat sealable

cross-linker

tensile stretch/flexibility

density/thickness

Our team has now broadened to include colleagues who will be working to develop ideas mentioned in earlier posts e.g. anti-viral, anti-bacterial film for face masks and activated wound healing films.

The polymer preparation includes much waiting time. Today, whilst waiting I read the article; Antiviral Potential of Algae Polysaccharides Isolated from Marine Sources: A Review, Azin Ahmadi et al, http://dx.doi.org/10.1155/2015/825203

The review states that marine algae are, “a rich arsenal of active metabolites with pharmaceutical potential, including anticancer, antitumor, antioxidant, antiviral.”

Further to this, marine algal derived polysaccharides are natural polymers which have antiviral properties which inhibit virus replication and the binding or internalisation of virus into host cells. Polymers named in the review inhibited mumps, hepatitis A, influenza B, and various absorption of viral STD’s; HPV & HIV.

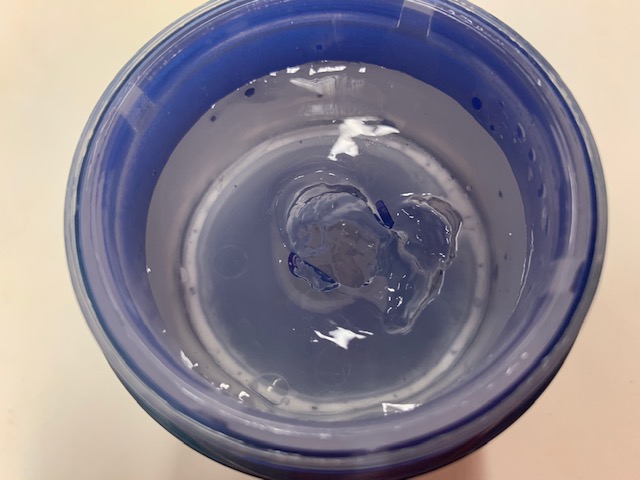

I recommended anti-viral polymers be developed as lubricant gels, condoms and underwear.

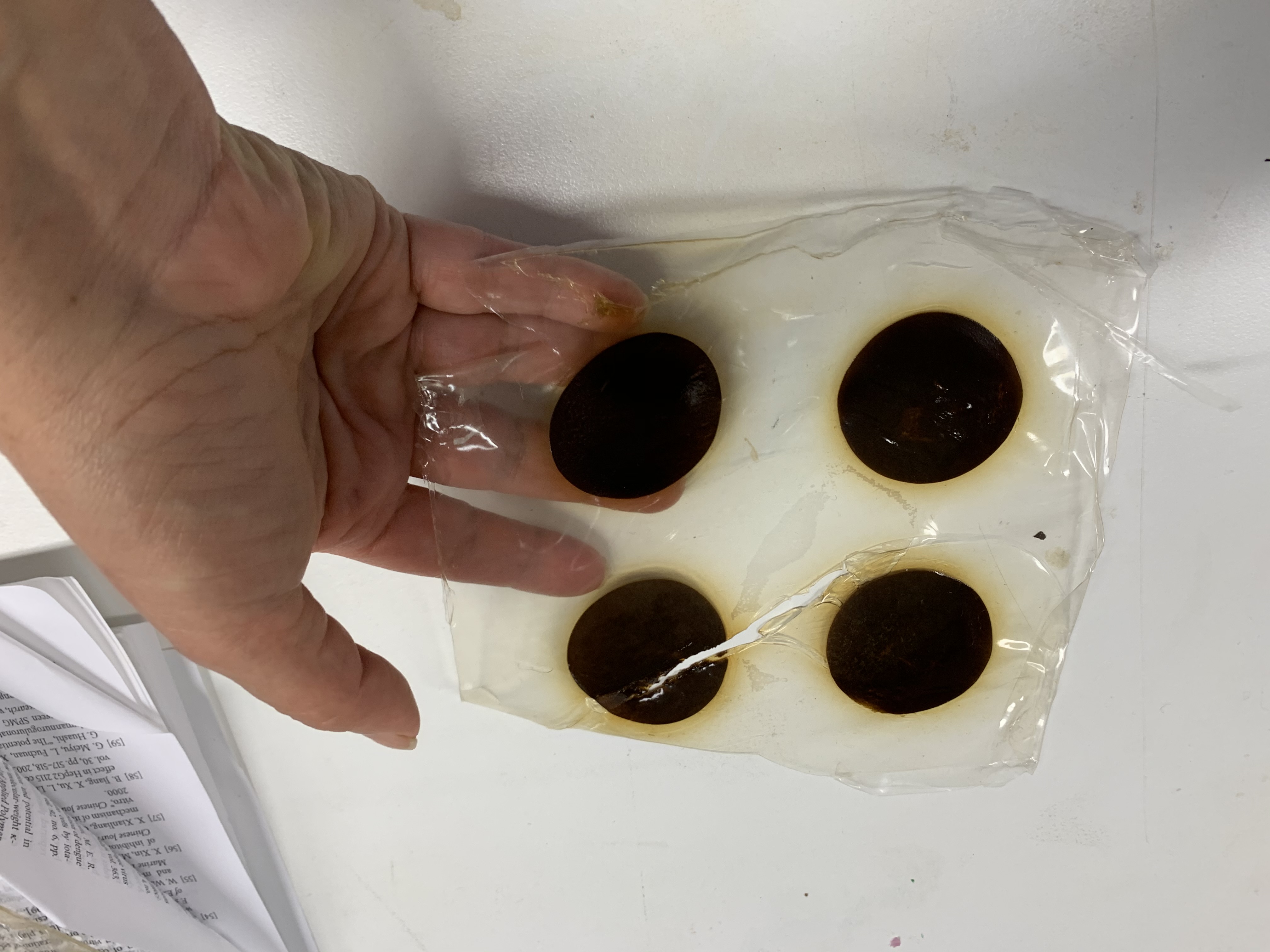

Peng Su and I brought my idea to fruition by developing a silicone free, anti-viral, marine algal polymer personal lubricating gel.

CMBD Staff member Kirsten Heimann forwarded a paper on an additional anti-viral as a suggested additive to the gel. The anti-viral is a protein that binds to sugars attached to HIV, it envelopes the protein and prevents it from binding to mucosal cell surfaces. It is also active against herpes viruses.

Alternative use for this lubricant can be as a base for hand sanitiser or ultrasound gel.

To make lubricant gels more socially acceptable they have been referred to as ‘personal protective’ gels.