Experimental films for regeneration, beauty, wearables and more…

Experimental films for regeneration, beauty, wearables and more…

Understanding how nature works is the first step forward.

Within a scientific environment we hack nature by allowing it to do its work for our purposes or by mimicking it. Discovery, however, is limited to our understanding.

We aim to keep materials as raw as possible as zero waste and minimal energy expenditure is our goal.

When we understand the natural properties of seaweed we can develop polymers with a spectrum of different attributes that are desirable for different applications; medicine, food, cosmetics, textiles, art projects. A think tank of individuals with diverse experience is useful to identify the potential within a material.

What are the applications? What are the desired properties?

What is the lifespan of the product? When will it degrade?

Will the product be soluble, water resistant, water proof?

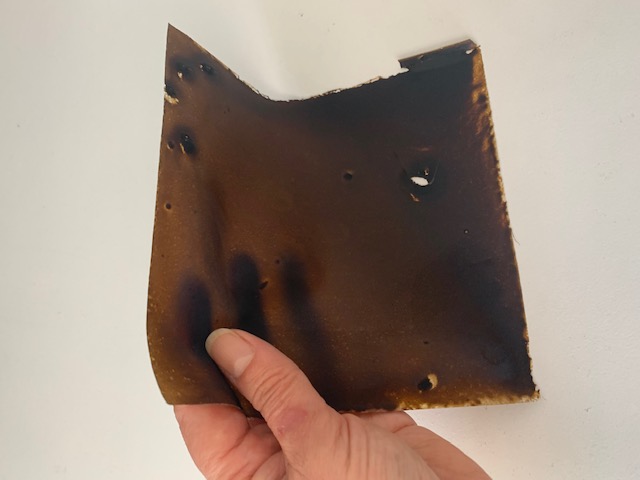

Our main focus is toward the production of films and 3D structures.

The Process:

-Raw materials are broken down.

-The scale of ingredients are refined to fine tune bio-polymer properties.

-Material chemistry is manipulated toward strength, flexibility and density.

-Adopting different drying conditions to change the structure.

Having worked with textiles, I saw that the water soluble bio-polymer film made by the Centre for Marine Bio-products Development (CMBD) from marine algae would work well as a fabric stabiliser. Soluble films are useful supports for piecing delicate or unruly materials. The films are then washed away.

This quick experiment to test the film showed that the polymer dissolves easily without disrupting the delicate fabric matrix.

A soluble seaweed polymer in a liquid spray form might be used as a fabric stiffener for industrial application and/or to hold shape in textile forms.

Moving my thoughts to the human body as tissue to be shaped and mended; soluble sprays, threads, fibres, films and scaffolds could be developed for bodily tissue support and healing as well as drug or nutrient delivery.

Together with bio-technologist Peng Su at CMBD we discussed future pathways for working with soluble and non-soluble matrices. Current research is toward unlocking the natural characteristics of seaweeds in order to understand them. We aim to chemically manipulate the raw materials for our own purposes in the most sustainable way possible.

The marine environment has evolved a balanced ecosystem of organisms and the bacteria to decompose them.

Sea-weed and sea-weed derived bio-plastics require bacteria to help decomposition. We identified the possible problems with biodegradability away from a marine environment. For sea-weed bio-plastic decomposition in all environments, Prof Chris Franco suggested polymers can be seeded with the bacteria to facilitate this. A variety of applications was discussed.

Conversely, sea-weed extracts were tested for innate antibacterial activity. If sea-weed bio-plastics are to be used for medical applications innate anti-bacterial activity would be useful.

I was able to assist, hands on, with the toxicity testing bacterial assay as I have used it to create earlier artworks focusing on the movement of bacteria across human, animal and environmental terrains. Within the broader context of my work, tracking the movements of anthropocentric activity is a recurring theme. Not only are we concerned with environmental impact of plastics pollution. Making sentient the movements of microbes is currently highly pertinent in a pandemic stricken global society.

Why seaweed bio-plastic?

South Australia is a marine macro-algae hot spot with many abundant and endemic species. The raw sea-weed material used in this project is sustainably sourced from wracks (beach cast material) at Beachport, South Australia. Unlike terrestrial plant based bio-plastics, sea-weed bio-plastics do not compete with resources cultivated primarily as food crops.

Sea-weeds have unique properties due to the challenging environment in which they grow. They are elastic and resilient to environmental stresses. Their unique structure makes them useful for flexible bio-polymer materials such as gels, films and 3D matrices. Sea-weeds are nutrient rich and can contribute health benefits in the areas of nutrition, healing, agriculture, aquaculture and cosmetics.

Since a large amount of plastic waste ends up in our oceans it is quite poetic that bio-degradable marine bio-plastics might return to the source to complete the carbon cycle; returning original chemical components to the sea.

Having a long-term focus upon ‘Prometheanism’, the lack of forethought toward the implications of technology, I believe this project probes technological problems, responsibility and potential futures. For me, the rethinking of plastics evokes hope.

One of the first lessons a scientist learns is that he/she must take responsibility for his/her own work.

Hence, if we produce plastic it is our problem.

What happens to the plastic we produce? Where does our plastic waste go? It goes somewhere.

Plastics have become an ‘out of sight, out of mind’ problem.

Its a fact that we don’t know exactly where our plastic waste ends up.

We need to develop awareness of our plastics problem.

The statistics:

Of the 78m tons of plastic is produced annually;

14% collected for recycling

14% burnt

2% gets recycled

40% landfill

30% pollutes the environment

(Dirty business: what really happens to your recycling, Sky News Published 29/1/2018 accessed 25/3/2020)

In the past we have exported our waste problem to China. China was an important market for plastic recycling; importing 10 million tons of plastic annually. It was a more cost effective option than recycling locally. Cheap overseas disposal options resulted in a lack of local investment toward new technologies. However China is now refusing to take plastic waste.

Further, exporting waste is passing on the problem. Our waste is our problem.

If plastic is too expensive & too problematic to recycle, can we design biodegradable plastic with a zero waste goal?

Project background.

Green Plastic – Blue Ocean is an interdisciplinary collaborative project between myself and Prof. Wei Zhang, director of the Centre for Marine Bio-products Development (CMBD), Flinders University College of Medicine and Public Health. We will experiment with future friendly bio-plastics generated from novel marine bio-polymer materials.

The word ‘plastic’ is problematic. Plastics are both useful and ubiquitous. Fossil fuel plastics are generally not readily bio-degradable, and this leads to the problem of plastic waste. Processing plastic waste is currently considered too difficult and expensive with technology available today. However, demand for plastics is rising. Microplastic health-related concerns are increasing due to food chain entry. Despite literature gaps, microplastics may be causing an increase in complications in multi-species diseases, cancer, and toxic effects due to bio-accumulation. The need to either reduce (difficult without legislation) or to replace non-degradable plastic is urgent.

We are also seeking insight toward human impetus as novel design requires cultural understanding. Working and building models together, we aim to develop questions, metaphors and realities, allowing us to rethink plastics.

How can we deal with the artificial environment humans have created? Can we reduce future impact upon society with next generation materials? How can we create cultural shifts to promote change and influence policy? If clean-up is impossible can we design with zero waste as our goal? How can we do better?

Seaweed (macro algae) polymers have unique properties which differ from terrestrial plant-based polymers. By utilising sustainably, seaweeds we will work with novel marine bio-materials to imagine and transition from petro-chemistry to green chemistry.

Plastic polymers derived from seaweed can be produced in forms that; are biodegradable, allowing nature to complete the carbon cycle by itself; contribute to carbon capture and storage.

Seaweed is probably one of the most prolific and underutilised renewable resources on the planet. Seaweeds grow faster than any land plant and provide benefits to the environment.

Through collaborative research and development between CMBD and myself, we aim explore the potential for marine seaweed bio-polymers whilst probing the world’s biggest ethical, environmental and technological challenges toward a more sustainable future for people, other species and ecologies.