Last week the laminated seaweed bio-polymer films I prepared were sent for high resolution imaging to observe properties by bio-technologist Wei-Lin.

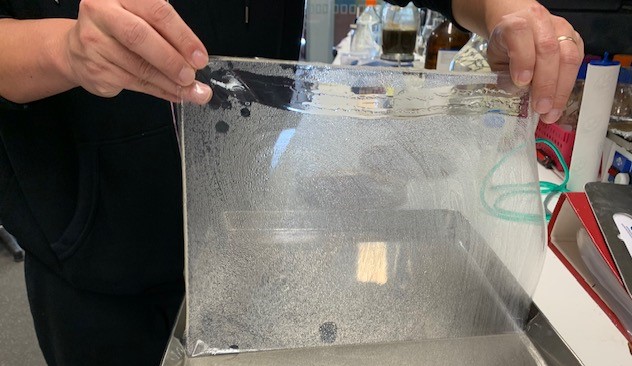

Samples of the laminated films were tested for water resistance by soaking in water.

Laminating successfully resulted in moisture resistant films but full immersion resulted in bleeding at cut edges. I expect that handling properties, e.g. cutting, stitching, moulding, will be much easier with this reinforced material.

The use of a craft cutter elicited both curiosity and amusement on the lab.

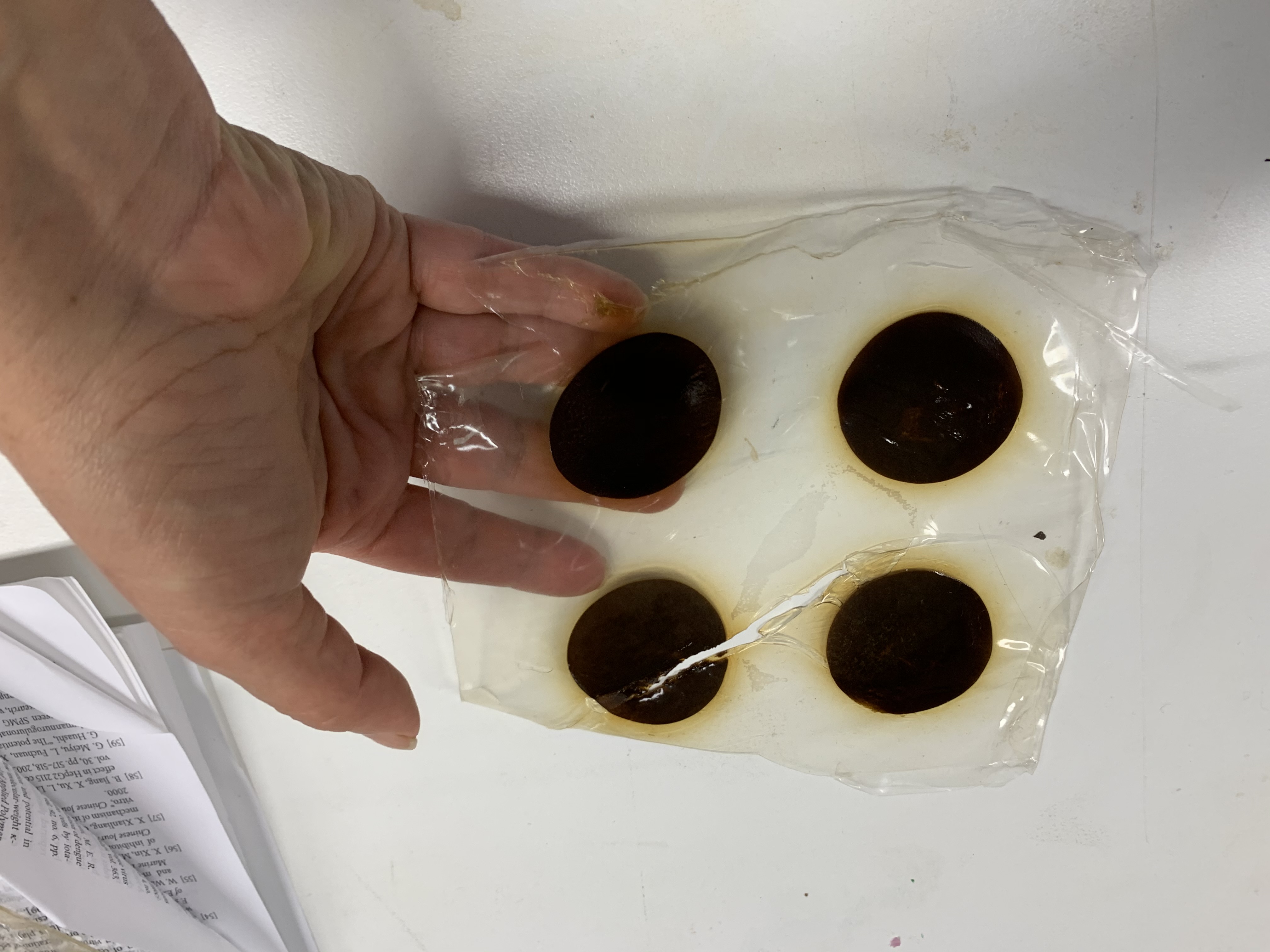

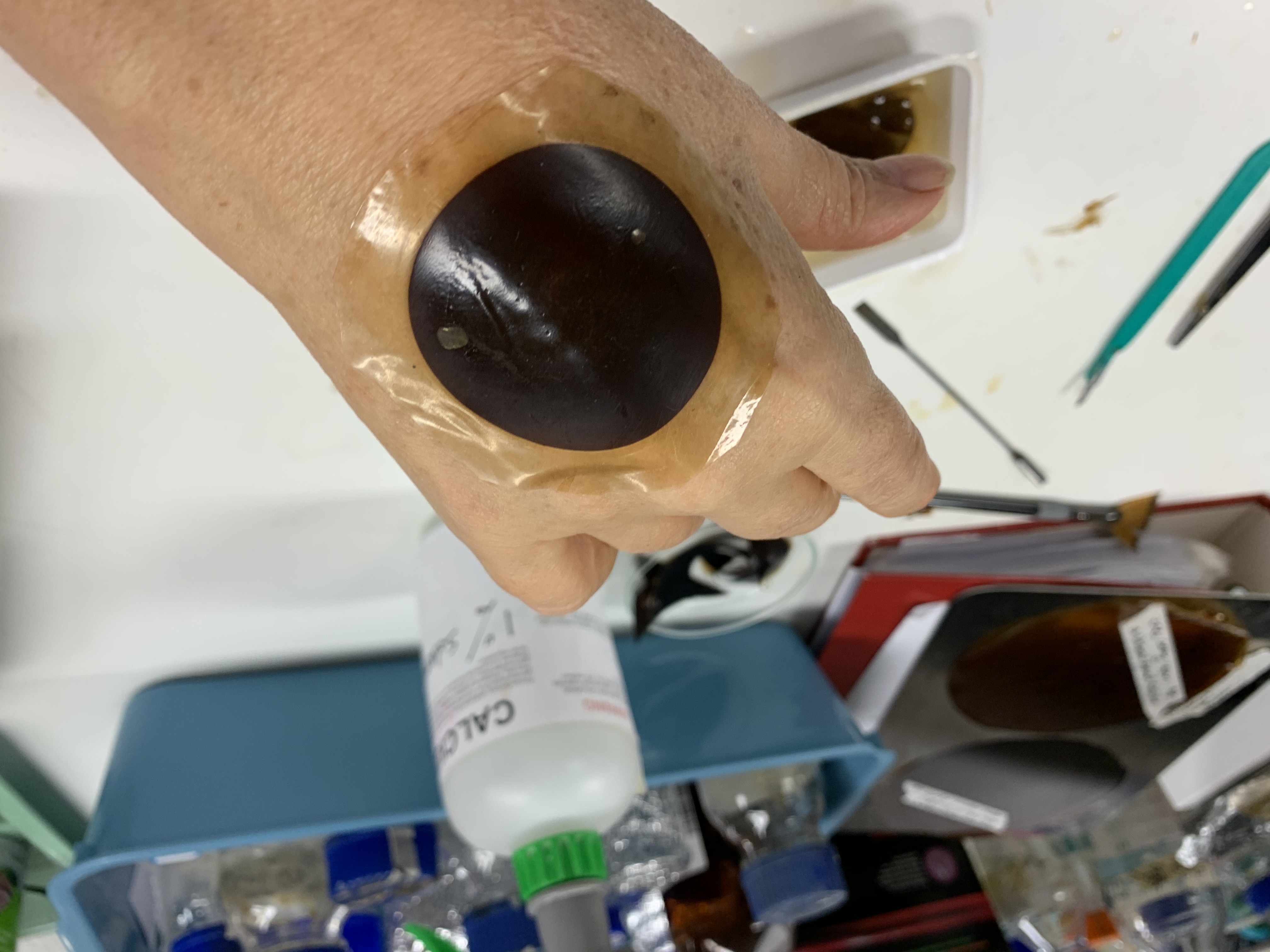

A craft cutter was used to create regular polymer film shapes. I laminated the shapes to stabilise the polymer before creating a composite film. The regular shape allowed for observation of 20% polymer swelling and transfer of seaweed tannin. It was determined that room must be allowed for polymer swelling to inhibit polymer film buckling and cracking.

Peng -Su experimented with chemical cross linker to inhibit swelling but this was discovered to be unsuccessful.

I am excited to experiment further with this water resistant ‘dotty’ film.

Making changes to the gel film formula;

As with other seaweed polymers the gel film responds to ambient weather conditions. Moisture absorbed into the film during wet weather causing polymer ingredients to precipitate out of the film.

Peng-Su and I made more gel films adjusting ingredients and film thickness. These film were not successful possibly due to bad weather.

We discussed the addition of beneficial marine derived antioxidants to these films.