I remember hearing, as a child, a story of seaweed being used to predict weather. Seaweed was nailed outside the home and if the air was moist the seaweed would re-hydrate, signifying that rain was eminent.

Behaving much like natural seaweed, the seaweed polymer ‘leather’ films we produced softened somewhat in damp weather and became difficult to sew and work with. We need to sort out this problem.

The brown algal derived polymers shown in earlier posts contain alginate and carageenan. These two ingredients are flexible and give seaweed the amazing ability to dry and re-hydrate many times over. Polymers made from alginate and carageenan need cross-linking to make them water resistant. To date we have not successfully produced a fully waterproof brown seaweed polymer but we are working toward this. My research revealed that agar produces water resistant polymers. (1)

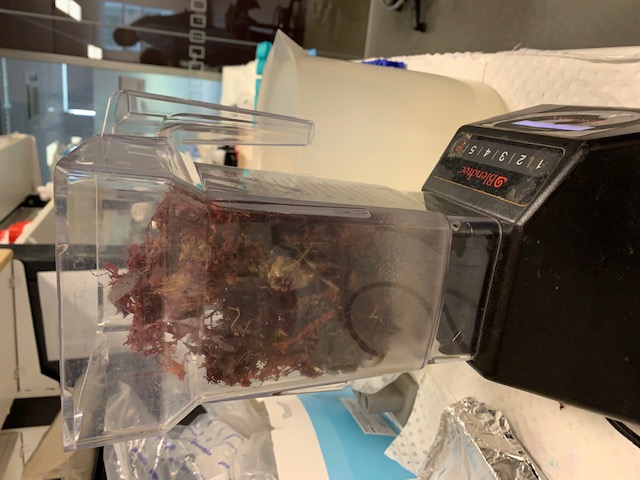

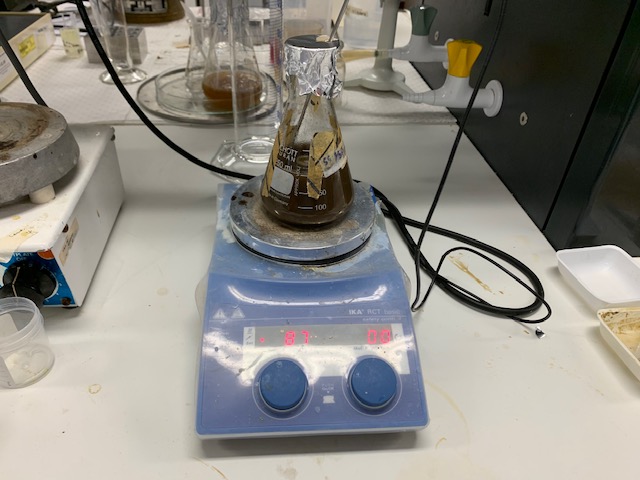

Bio-technologist Peng Su advised that red seaweed contains agar. We ground dried samples of red seaweed collected from Beachport South Australia and made experimental polymer films combining brown and red seaweed derivatives.

Pharmaceutical grade seaweed polymer blends were made resulting in some excellent films which retained fine surface textures and I expect would be good to print on. I will try to run though a printer at some stage.

We also spoke of experimental spray application of liquid polymer and cross linker, inspired by Professor Fiona Wood. (2)

(1) Peluso Fara, Material Driven Design, Sculpting with Bioplastic Textile, Art Laboratory Berlin, zoom live, 6 May 2020

(2) Wood F, Keynote:The Goal of Regeneration, Quite Frankly Conference, Symbiotica, UWA, Perth Oct 2018,