As part of this ANAT Synapse art/science residency with CMBD, and another art project (TBA), I have been examining the concept of a hybrid seaweed/mammalian biopolymer material.

This fits with my longstanding interest in the Chimera as hybrid entity.

Bio-compatible (mammalian cell compatible) polymers require certain attributes i.e. water resistance and open structure.

Experimenting with water resistance.

In earlier experiments I laminated natural seaweed biopolymer films with water resistant seaweed polymers to improve them.

After self-directed research, I added wax to polymers to further water resistance.

Initial drying showed marked shrinkage and cracking, however the material rehydrated well without excess swelling as with other polymer formulae.

I tweaked the formula and solved the cracking problem.

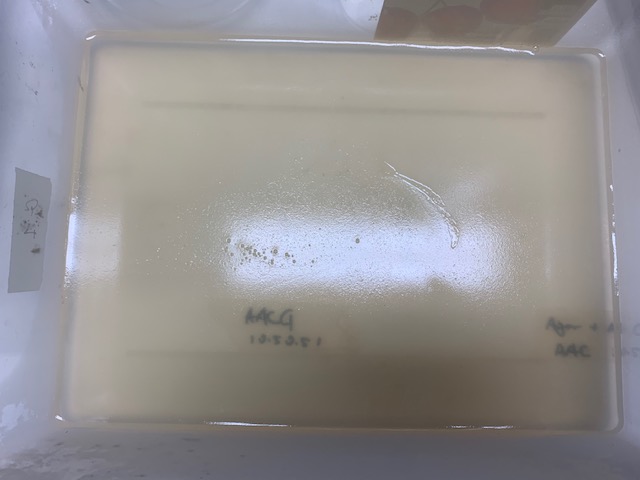

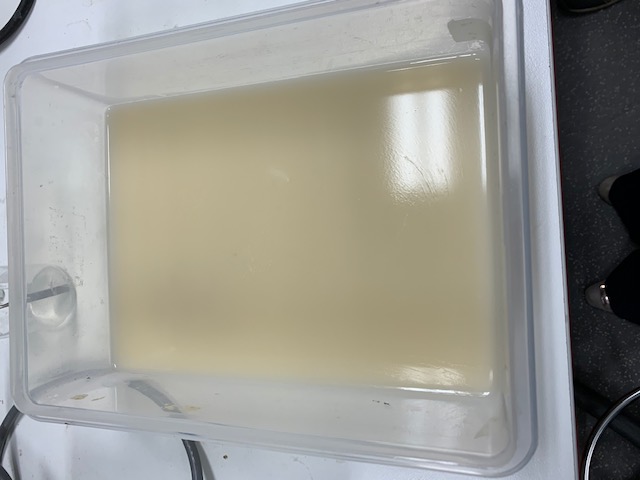

Below: Polymer before and after soaking in water, some swelling (less than regular polymer) and film remained strong.

As well as a film, I made simple hollow forms (vessels) to further test this bioplastic for water holding ability.

To reduce shrinkage, I experimented with polymer ratio to make denser films.

Testing biopolymer pH

In another direction this week with biocompatible polymers:

For optimal cross linking of bioplastic and biopolymer. Peng Su and I tested earlier formulations for pH.

Freeze drying

To increase bio-compatibility (bio-compatible polymers can be used for bodily regeneration therapies e.g. cell culture), and breathability (for diverse use), the polymer was shocked using a variety of freezing methods.