French literary theorist Roland Barthes explained in his text “Death of the Author”, that it is not literary convention alone, nor solely the writer that brings meaning to a text but further interpretation comes from those who subsequently read it. From my experience, similar can be said of working with a medium, product or technology. It may be designed for a certain use, however it is the alternative applications that people creatively apply to it that I find fascinating. These uses can be defined as hacking.

There is often a lag between the development of a new product or technology and the understanding of its full potential or risk. These good or bad consequences have been observed since ancient times and explained through such things as Pandora’s Box and Promethean myth. We simply have to look at plastics to observe this in action.

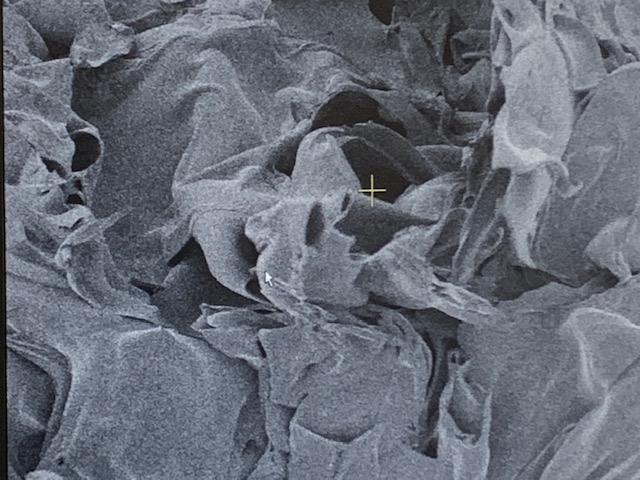

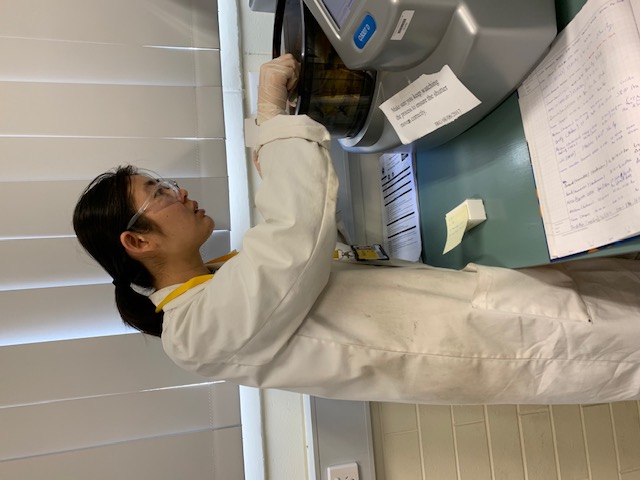

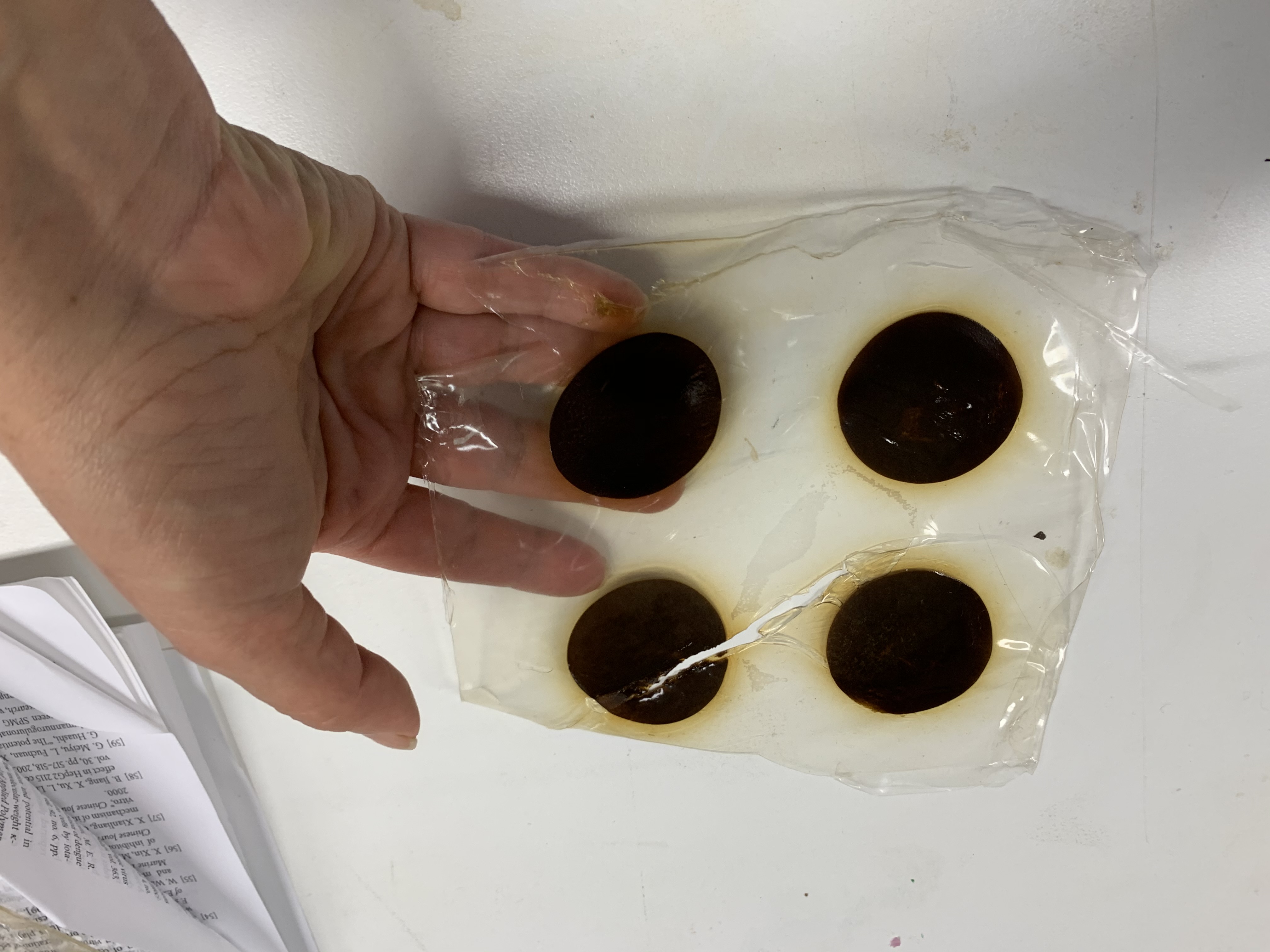

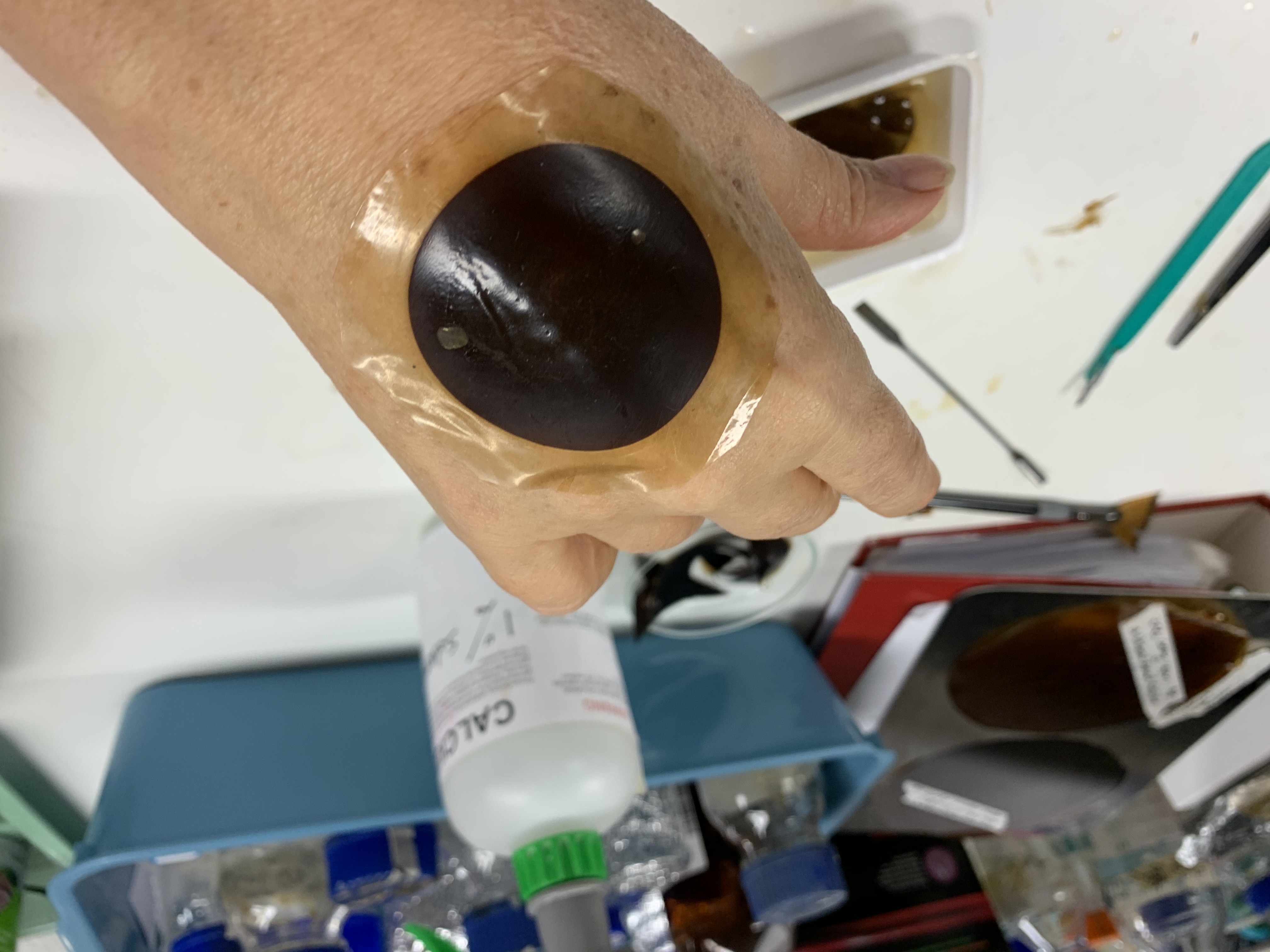

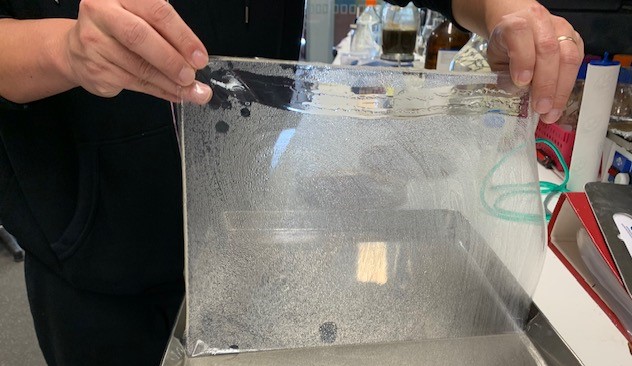

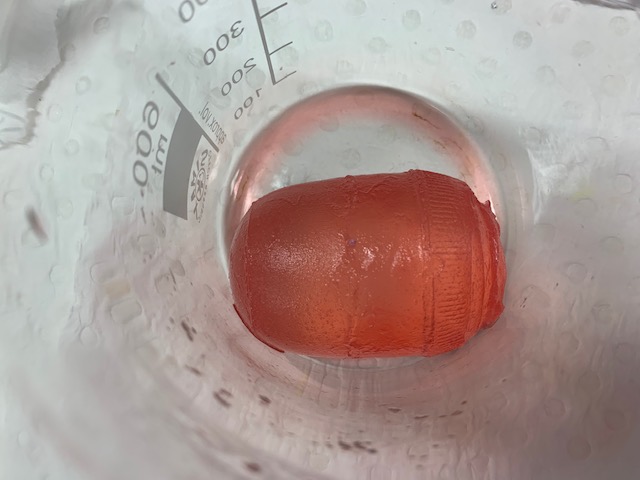

Further, together with CMBD, we have found that certain seaweed polymers can have multiple potentials e.g. from gel, to fibre, to film, to matrix, and can have broad applications.

One of the attributes of seaweeds is that certain varieties contain tannins. CMBD are interested in seaweed tannins for their health benefits. Tannins are bio-molecules that bind to proteins. They are also available in tea and wine. Tannins protect against oxidative stress; an imbalance in the cell’s ability to repair itself. (Free radicals steal electrons from molecules and make them unstable.)Tannins have antioxidant potential, protecting against oxidation as they can donate electrons to free radicals to make them more stable.

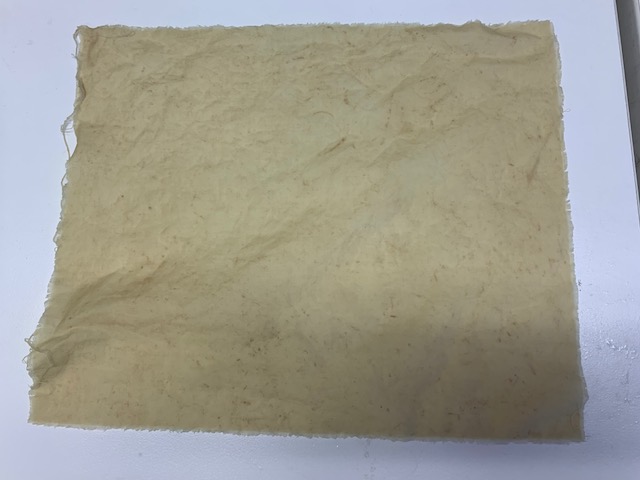

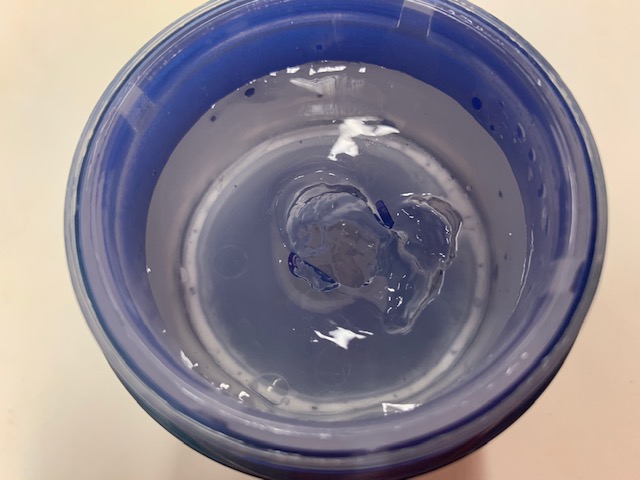

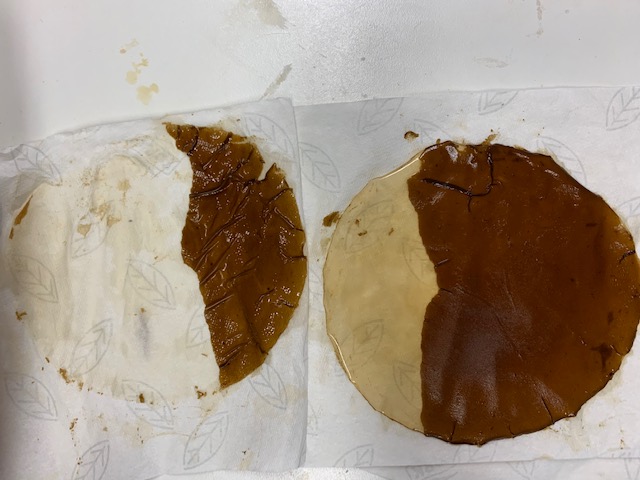

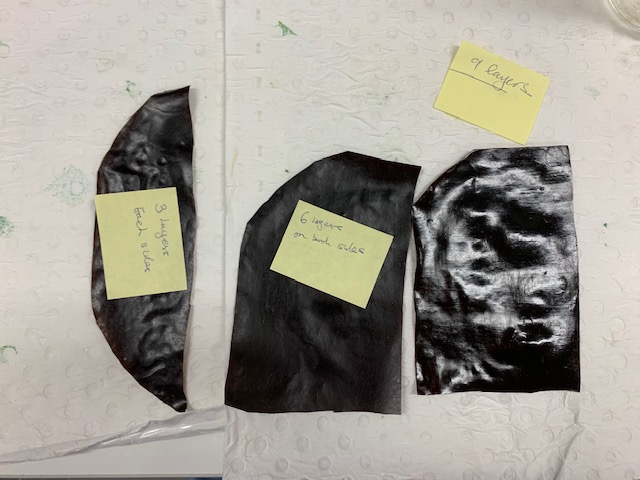

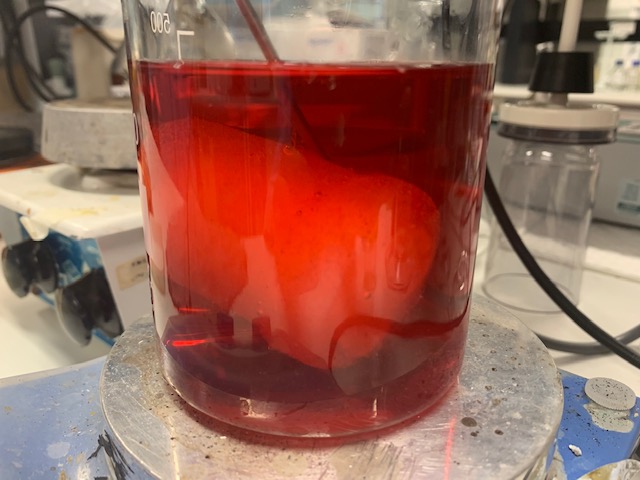

After observing the staining capacity of the seaweed tannins when pressing and drying samples between paper, I decided to experiment with the seaweeds we use to make polymers to make fabric dyes. Fabric dying processes were researched and I found that certain chemicals we use to precipitate the bioplastic polymers are also used to create fabric dyes.

Natural fabric dyes are said to be more ecologically friendly than synthetic dyes.

To date I have produced subtle skin toned dyes from the species Ecklonia Radiata and Durvillaea (Bull kelp). These fit within my go to palette of bodily hues; skin, fat, flesh and blood.