Moist seaweed bio-polymer film as a comfortable dressing

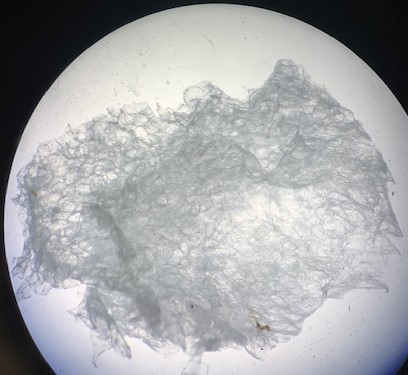

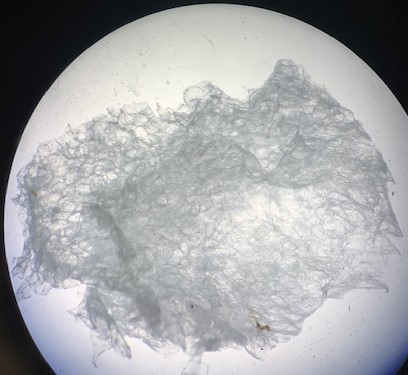

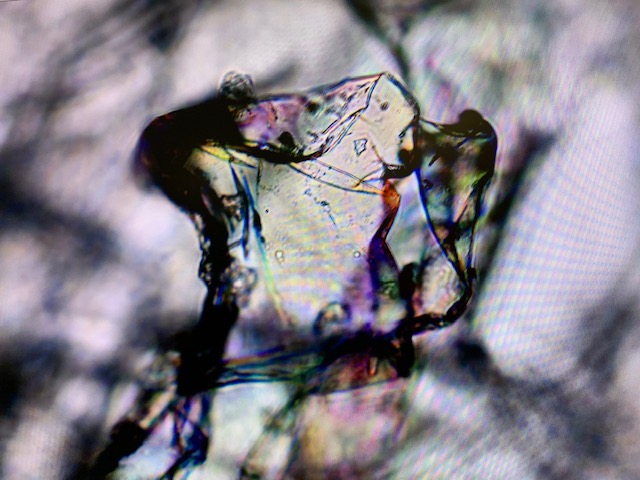

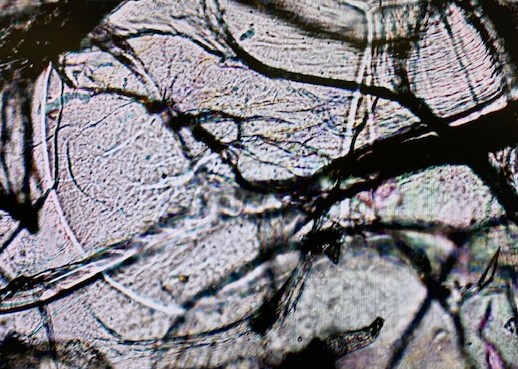

Microscopy of film above before soaking showing porosity

Future trouble shooting required as soaking film results in rolling

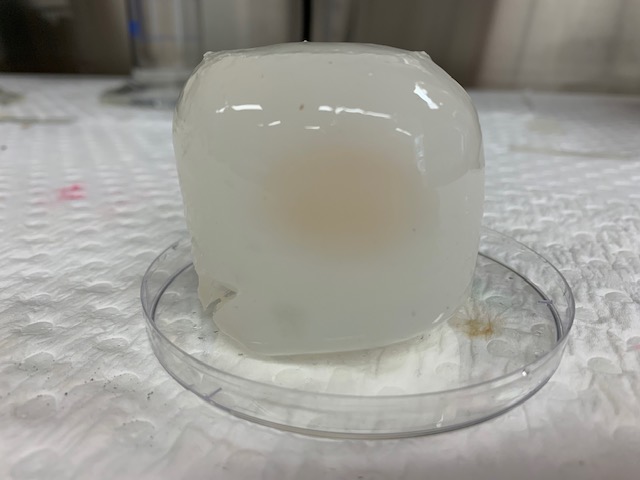

Moist seaweed bio-polymer film as a comfortable dressing

Microscopy of film above before soaking showing porosity

Future trouble shooting required as soaking film results in rolling

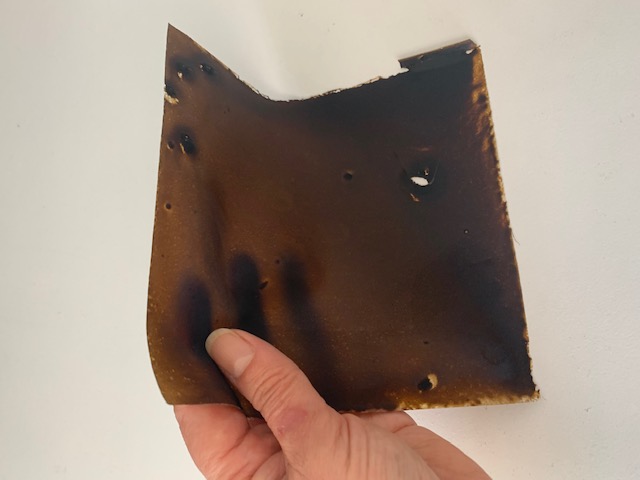

The project has progressed well thus far but it has not been without failures. Failures are an important part of the learning process allowing for the identification of troubleshooting strategies and leading to improvements.

Failed seaweed polymer film 31/5/2020

Failed seaweed polymer films 31/5/2020

Failed seaweed polymer water proof film 20/5/2020

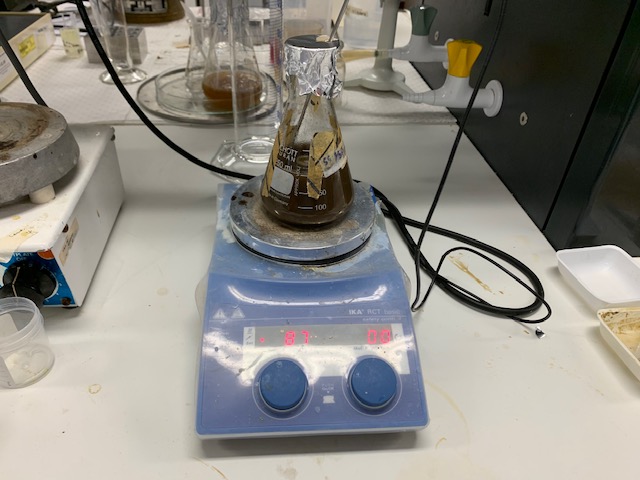

Failed to fully cross link 3D polymer scaffold 20/5/2020

Faulty application seaweed skin polymer ‘mask’ 15/4/2020.

Cross-linked moist seaweed polymer film failed to remain flat 20/5/2020

I remember hearing, as a child, a story of seaweed being used to predict weather. Seaweed was nailed outside the home and if the air was moist the seaweed would re-hydrate, signifying that rain was eminent.

Behaving much like natural seaweed, the seaweed polymer ‘leather’ films we produced softened somewhat in damp weather and became difficult to sew and work with. We need to sort out this problem.

The brown algal derived polymers shown in earlier posts contain alginate and carageenan. These two ingredients are flexible and give seaweed the amazing ability to dry and re-hydrate many times over. Polymers made from alginate and carageenan need cross-linking to make them water resistant. To date we have not successfully produced a fully waterproof brown seaweed polymer but we are working toward this. My research revealed that agar produces water resistant polymers. (1)

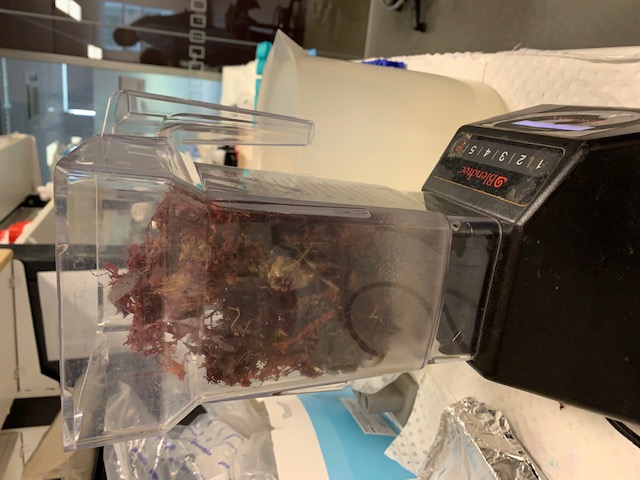

Bio-technologist Peng Su advised that red seaweed contains agar. We ground dried samples of red seaweed collected from Beachport South Australia and made experimental polymer films combining brown and red seaweed derivatives.

Pharmaceutical grade seaweed polymer blends were made resulting in some excellent films which retained fine surface textures and I expect would be good to print on. I will try to run though a printer at some stage.

We also spoke of experimental spray application of liquid polymer and cross linker, inspired by Professor Fiona Wood. (2)

(1) Peluso Fara, Material Driven Design, Sculpting with Bioplastic Textile, Art Laboratory Berlin, zoom live, 6 May 2020

(2) Wood F, Keynote:The Goal of Regeneration, Quite Frankly Conference, Symbiotica, UWA, Perth Oct 2018,

What is our relationship to plastic?

Where does our waste go?

‘Óut of sight out of mind’ is a re-occurring scenario within the plastics problem.

Biodegradable Seaweed Polymer Crisis Mask links two current states of crisis; the Covid19 situation and the plastics water pollution problem. Crisis Mask is inspired by images in social media of discarded face masks ending up in our waterways.

https://www.unilad.co.uk/news/discarded-face-masks-and-gloves-are-rising-threat-to-ocean-life/

Referring back to this microscopic image of the freeze dried material I took at CMBD.

The freeze dried matrix looks similar to the microscopy of Pelling Lab’s apple and microscopy of Vacanti’s ear mouse (image below). The Vacanti mouse has proved inspirational to several artists working with wet biology including Tissue Culture and Art Project, Stelarc and myself. The Ear Mouse has informed my chimeric interfaces including; Chimera series (2001), Blood flowers (2003), Man A Plant (2006), Matrix (2016) and The Colonised Body (2016).

(above) ‘Polyglycolic acid polymer seeded with dissociated cells.’ Vacanti’s ear mouse (Forkus Brittany, Ear on a Mouse, OpenWetWare.org)

“One of the pivotal considerations in the design of this polymer scaffold for the engineering of replacement tissues is in regards to the selection of an appropriate matrix material. This ideal scaffolding material would need to have several essential characteristics and tuning capabilities for proper functionality in this application for it must be–biocompatible, mechanically stable, flexible, controllably degradable, resorbable, and capable of making specific chemical interactions with the seeded cells. In terms of biocompatibility, it is essential that the polymer avoids eliciting an undesired immune response in the host which could ultimately result in immune rejection and procedural failure. Physically, the matrix needs to have a certain degree of mechanical stability and flexibility to ensure that it can provide the necessary support and space for tissue formation, so that it can be easily designed and constructed into variable shapes and structure, and it must be able to withstand the procedure and in vivo environment in order to maintain this structure upon implantation. Finally, some desirable tuning capabilities of the ideal polymer scaffold would entail tunable degradation characteristics, the matrix should be capable of resorbing to the body while leaving only natural, functional tissue, and the manipulation of surface chemistry to dictate desired interactions between the seeded cells and the matrix surface.’ (Forkus Brittany, Ear on a Mouse, OpenWetWare.org)

The Pelling Lab apple and the Vacanti mouse matrices are both layered with collagen for cells to adhere to. Perhaps collagen can be swapped out for seaweed alginate if biocompatable.

Current range of Polymer materials

-liquid, 2D film, 3D model

methods for applying chemical cross polymer

-spraying, dipping, soaking

drying methods

-air, oven, freeze -20 Celcius, freeze dry

I am looking for a casting material that will hold surface detail with reduced distortion/shrink rate. Further to this, can we seed the polymer with cells? Can we make a matrix that maintains cell viability? Can the polymer maintain form (and what is the optimum duration) in a growth medium? Can growth be maintained in a bioreactor?

Problems identified in earlier 3D scaffold testing are polymer shrinkage, bulging & distortion and loss of surface detail due to soft consistency before cross linking.

Solution:

-densify polymer

-freeze -20C to minimise shrinkage

-slow down cross linkage by reducing temperature, amount of chemical and dip rather than soak

After cross linking in frozen state surface detail and shape are maintained.

Since 2001, human-plant & human-animal hybrids, Chimeras, have manifested in my artworks.

In 2013, I met Andrew Pelling when we participated in the Toxicity bio-art project in Winnipeg Canada. Pelling was showing his work “Repurposed” which included ear shaped apple sculptures supporting human cells. The research article below co-authored by Andrew Pelling might provide insight toward seeding our scaffolds with cells.

Modlevsky et al, Apple Derived Cellulose Scaffolds for 3D Mammalian Cell Culture, journals.plos.org, 2014

A simple cylinder shape was selected to create 3D bio-polymer prototypes. Simplicity of form is desired at this stage to make variations evident. The same 3D bio-polymer formula was manipulated via different drying methods; aqueous storage, freeze drying and air drying. We are testing for moisture holding capacity and shrink rate.

The samples cast with some distortion; external shrinkage causing bulging due to chemical cross-linking of the polymer. Sample (a) and (c) were soft and nice to carve. The freeze dried material was porous and open; possibly useful for seeding with other materials.

Only the structure of the freeze dried sample (b) is visible under microscopy. A combination of films and fibres were observed.

Air dried, sample (c) continued to shrink and bulge. Microbial contamination is apparently a ‘good thing’ as it evidences the ability of the polymer to support life.

Aqueous environment, sample (a) showed markedly less shrinkage and was also contaminated.

Unrefined experimental natural seaweed 3D bio-polymer was produced toward the goal for zero waste and less energy consumption.

Experimental films for regeneration, beauty, wearables and more…

Understanding how nature works is the first step forward.

Within a scientific environment we hack nature by allowing it to do its work for our purposes or by mimicking it. Discovery, however, is limited to our understanding.

We aim to keep materials as raw as possible as zero waste and minimal energy expenditure is our goal.

When we understand the natural properties of seaweed we can develop polymers with a spectrum of different attributes that are desirable for different applications; medicine, food, cosmetics, textiles, art projects. A think tank of individuals with diverse experience is useful to identify the potential within a material.

What are the applications? What are the desired properties?

What is the lifespan of the product? When will it degrade?

Will the product be soluble, water resistant, water proof?

Our main focus is toward the production of films and 3D structures.

The Process:

-Raw materials are broken down.

-The scale of ingredients are refined to fine tune bio-polymer properties.

-Material chemistry is manipulated toward strength, flexibility and density.

-Adopting different drying conditions to change the structure.

Having worked with textiles, I saw that the water soluble bio-polymer film made by the Centre for Marine Bio-products Development (CMBD) from marine algae would work well as a fabric stabiliser. Soluble films are useful supports for piecing delicate or unruly materials. The films are then washed away.

This quick experiment to test the film showed that the polymer dissolves easily without disrupting the delicate fabric matrix.

A soluble seaweed polymer in a liquid spray form might be used as a fabric stiffener for industrial application and/or to hold shape in textile forms.

Moving my thoughts to the human body as tissue to be shaped and mended; soluble sprays, threads, fibres, films and scaffolds could be developed for bodily tissue support and healing as well as drug or nutrient delivery.

Together with bio-technologist Peng Su at CMBD we discussed future pathways for working with soluble and non-soluble matrices. Current research is toward unlocking the natural characteristics of seaweeds in order to understand them. We aim to chemically manipulate the raw materials for our own purposes in the most sustainable way possible.